Recently, Jiangsu Langsheng Life Technology Co., Ltd. (hereinafter referred to as "Jiangsu Langsheng"), a wholly-owned subsidiary of ISUN, has received good news and won the ISO13485 certification again. This key achievement is not only a high recognition of Jiangsu Langsheng's quality management in hemodialyzers but also a powerful testament to its continuous progress and rejuvenation since joining ISUN.

Re-upgrade

Comprehensive Deepening of Quality Management

EVERYLIFE EVERYDETAILS

ISUN has always regarded quality as the lifeline of the enterprise. It adheres to the quality control standards of "meticulousness, full control, and strict release" in every production link and is committed to providing high-quality, safe, and efficient medical solutions. The concept of "revering life and being meticulous" is deeply rooted in ISUN's corporate culture and is also a principle that Jiangsu Langsheng firmly follows.

In terms of quality management, Jiangsu Langsheng has been constantly expanding and deepening. Since its establishment, the company has formulated strict and detailed quality control processes according to high standards, covering every production link. With the continuous development of the industry and the dynamic changes in market demand, in order to ensure that product quality can meet the increasingly higher requirements, Jiangsu Langsheng has actively introduced advanced quality management concepts and methods. This year, obtaining the ISO13485 certification has become a key goal, and all employees have worked together and actively participated in the relevant work.

For products such as sterile disposable hollow fiber hemodialyzers involved in this certification, during the research and development stage, Jiangsu Langsheng fully considered the needs of patients and clinical application scenarios, and organized a professional team to conduct rigorous demonstration work to ensure the safety, effectiveness, and rationality of the product design. During the development process, it strictly followed relevant standards and specifications and invested a large amount of resources in technology research and development and testing to ensure the stable performance and reliable quality of the products.

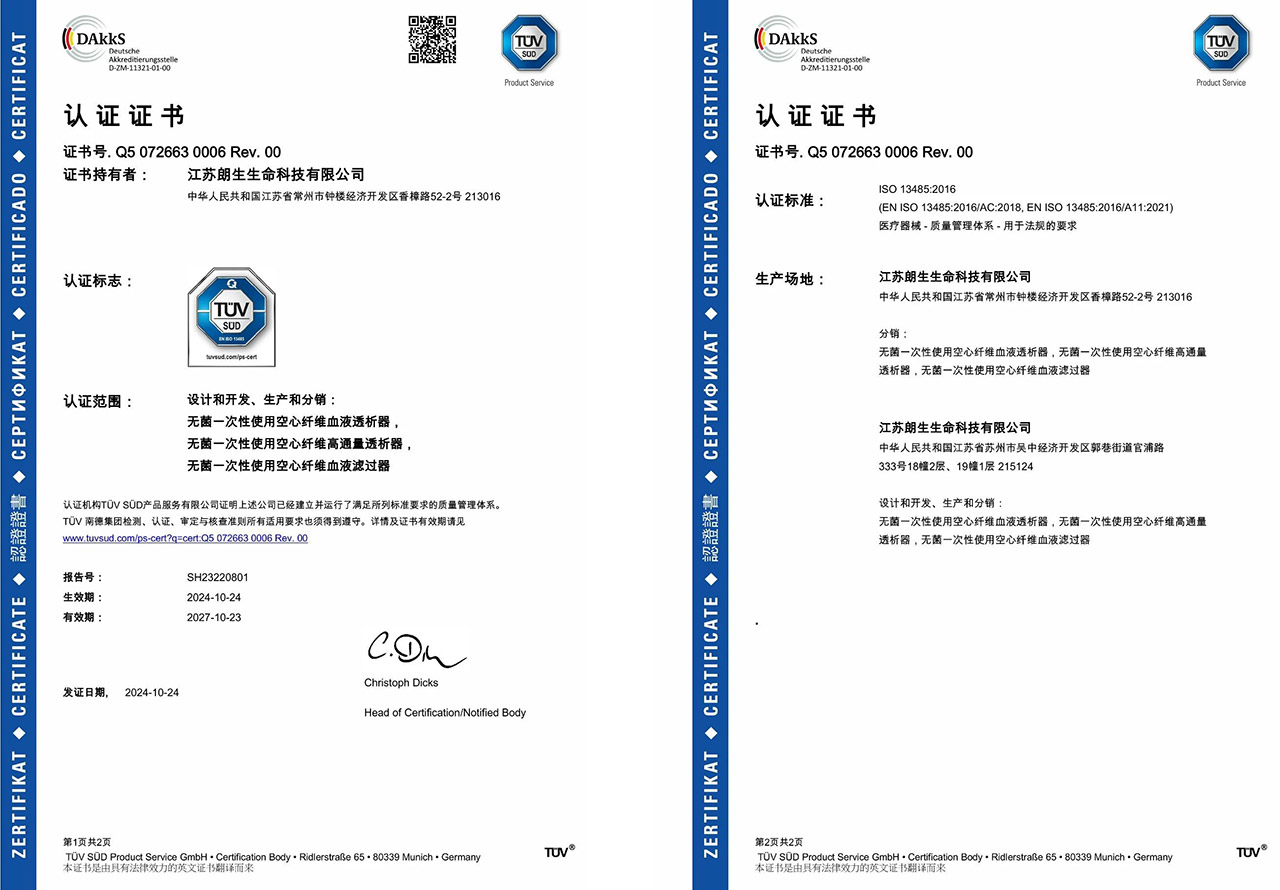

After the unremitting efforts of all employees, Jiangsu Langsheng finally won the ISO13485 Medical Device Quality Management System certification. TÜV SÜD, the certification body responsible for this certification, is a globally renowned certification institution and enjoys a high reputation internationally for its professional, rigorous, and authoritative certification system. The fact that Jiangsu Langsheng has obtained the ISO13485 certification from TÜV SÜD fully demonstrates the high quality and reliability of its products and is another testament to Jiangsu Langsheng's in-depth cultivation in the field of blood purification.

Strong Closed Loop

Technology Empowers Quality Innovation

EVERYLIFE EVERYDETAILS

Regardless of how the market environment changes, the enterprise strength and reputation built on quality are the cornerstone for dealing with everything. The quality of medical devices is directly related to the life and health of patients. Therefore, it is necessary to establish a quality management closed loop with higher requirements and higher standards. The ISO13485 certification requires the company to strictly follow quality standards in all aspects such as the design, development, production, and service of medical devices.

The production base of ISUN's Changshu headquarters, which recently started construction, integrates major processes such as injection molding, spinning, assembly, and sterilization, and is fully committed to creating an intelligent full-process production mode. Based on the technical foundation of intelligent manufacturing, the production line is equipped with multi-point AI visual inspection equipment to achieve 100% full inspection, effectively avoiding the problems of missed inspection and misjudgment that may occur in manual inspection, and building a solid defense line for product quality. The Changshu headquarters production base has introduced a digital and intelligent production scheduling system, which can efficiently complete the automated warehousing, logistics, and distribution of the entire process from order receipt, raw material procurement, semi-finished product processing to finished product distribution, ensuring the precision, efficiency, and stability of the entire production process, further strengthening the company's quality management system, and providing a powerful guarantee for the production of high-quality blood purification products.

From the pursuit of quality at the beginning of the company's establishment to the current re-winning of the ISO13485 certification, quality management has always been the core of the company's development. ISUN and its subsidiary Jiangsu Langsheng will, as always, adhere to their original aspirations, intensively cultivate the path of quality, continuously strengthen the quality management system, and treat every link with a rigorous attitude. From the strict screening of raw materials to the precise application of advanced processes, from the careful research and development of professional teams to comprehensive and detailed quality inspection, they will practice the corporate philosophy of "revering life and being meticulous" with practical actions.